“The new Block V fast attack submarines of the Virginia class being built for the US Navy are over budget and behind time, according to a government monitoring organization. In a study, the US Government Accountability Office (GAO) claimed that issues with human resources were to blame for the development of this ailment. “Overall increasing labour demand” and “other issues, such as proportionately fewer experienced personnel” are to blame, according to the report. If the labour shortage issues in the Block V programme continue, the GAO questioned whether the Navy could go forward with its Block VI programme.

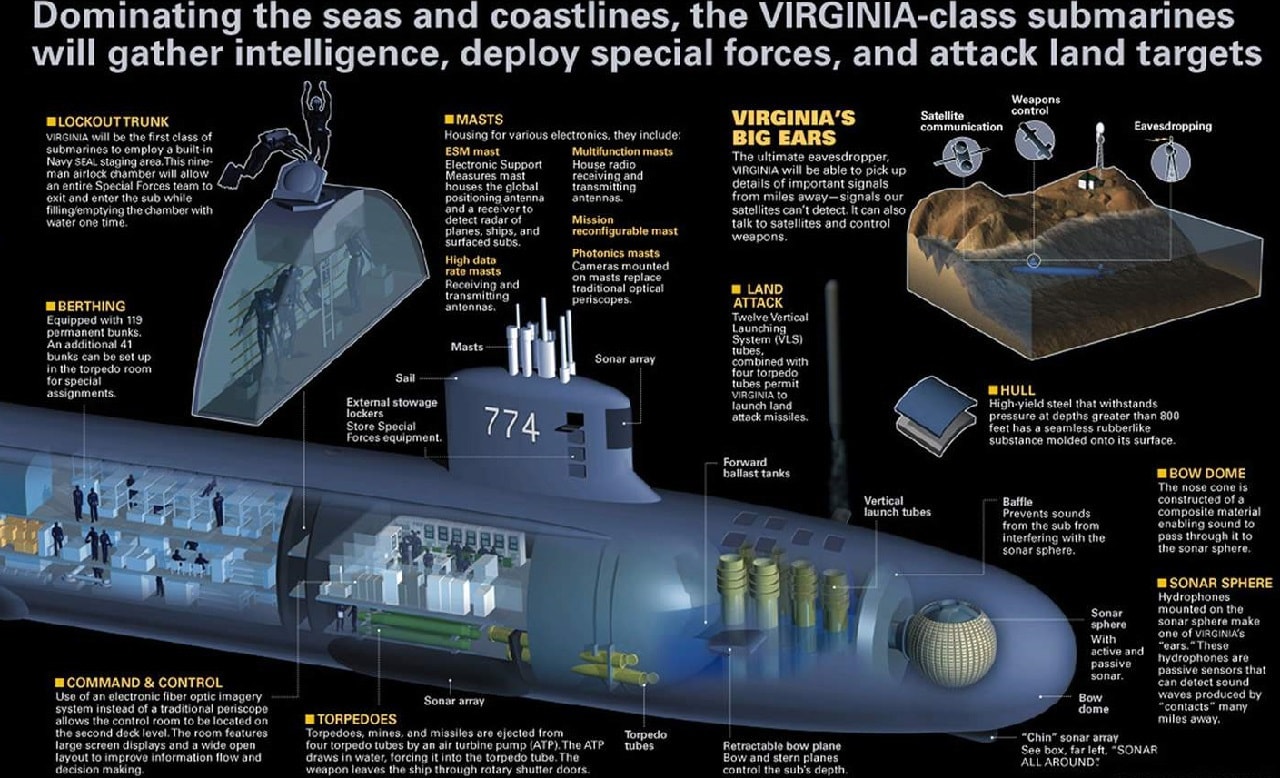

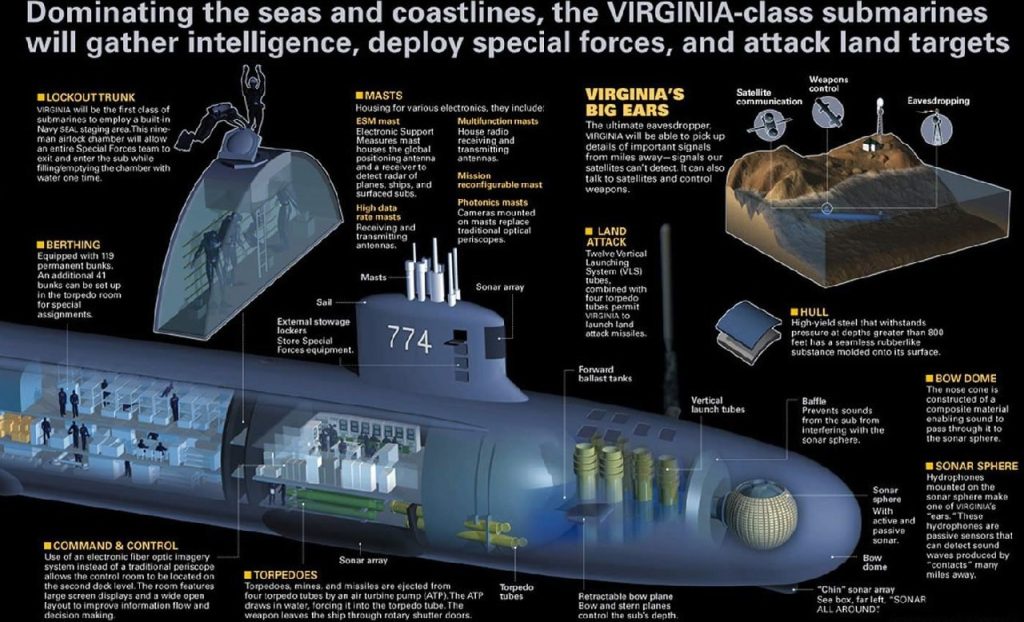

The Block V submarine of the Virginia Class has extra space for weaponry. In a lengthy segment behind the sail, these vessels will carry an additional 28 missile slots. As a result, the submarine will grow in length, but the number of tomahawk-sized weapons will rise to 65. The Seawolf Class has space for 50 Tomahawk cruise missiles, but this is more than that.

The Navy intends to construct 72 to 78 brand-new assault submarines. There will be ten Virginia Block V boats in all. More sensors and a new weapons module will be aboard Block V. Four more vertical launch tubes will be installed as part of an 84-foot-long expansion, producing more Tomahawks. Seven missiles may be fired from each box. The Virginia Payload Module is this addition.

The Block V batch of new Tomahawks, which have been installed, will be enhanced to include an anti-ship capability. That is a significant improvement because, in a battle with China, the Block V boats would be helpful in the Indo-Pacific. The United States Navy intends to use as many anti-ship missiles as possible in the conflict since China has the largest Navy in the world.

GAO is concerned that these renovations will take longer than anticipated and cost more money. The GAO thinks the Navy prioritized the Block V modifications while building the Columbia-class submarine. Labour scarcity is the result of this. Electric Boat, a division of General Dynamics Corporation, has a programme to attempt to recruit more women to work as welders since there is a shortage of welders in the industry.

The second primary submarine manufacturer, Huntington Ingalls Industries Newport News Shipbuilding, likewise struggles with a lack of welders, electricians, riggers, and other shipyard personnel. Both businesses have informed the Navy that these human resources shortages will continue to challenge the building of submarines. The companies fear that they may need to hire staff with less training and expertise.

The GAO has decided that the first delivery of the first three Block V Virginia-class submarines would be delayed. Additionally, more money will be spent than was initially planned because of these delays. Before 2022, the Navy had predicted that its labour issues would be resolved, but this has not happened.

That implies the plans to upgrade the Block VI submarine will be impacted. The Navy believed Block VI would serve as a “bridge” to the next-generation SSN(X) programme, a new class of attack submarines, in 2020. The boats of Block VI are expected to be quieter than Block V. Upgrades for Block VI were expected to start in FY24 and be delivered in FY28. With the delays and expenses resulting from the Block V labour shortage problem, such deadlines don’t seem realistic.

In the past, the Navy relied on business to find new employees for shipyards. The service department is now reexamining this technique and developing new ideas to get additional employees to its submarine construction facilities. Focusing on the comparatively high salary these positions provide and letting people know they would be ideal for women is one strategy to solve this issue. The Navy will also begin educating high school and community college students about the financial benefits of working in the shipbuilding industry and the personal satisfaction of helping defend the nation.

Human error, including poor planning and execution, is often blamed for delays and expense overruns. Delays and financial difficulties may also result from supply chain bottlenecks. Now, the issue is more related to human resources. The Navy must ensure it can hire top talent who want to make shipbuilding a long-term profession to compete with China’s naval shipbuilders. The most excellent submarines in the world cannot be delivered to warfighters without an adequate industrial basis.